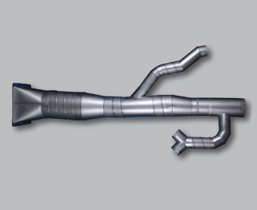

Spiral pipe is formed from a coil of metal into a rigid steel tube with a 4-ply spiral lockseam. It has smooth interior for low friction loss with the grooved seam entirely on the outside. This pipe has a resistance to crushing approximately 2 1/2 times that of longitudinal lockseam or welded pipe.

The advantages of high pressure Spiral pipe compared to traditional rectangular duct are numerous and compelling:

Attractive appearance :

exposed Spiral duct is attractive and is frequently specified by architects because of its superior aesthetic appeal. Paintable Spiral duct can be finished to blend in with, or stand out from, the indoor environment.

Economical to install :

• Easier to install through and around structural framing

• Longer spans reduces installation operations and the number of connections and hangers required • Connections are made quickly and easily, and are easier to seal.

Lower cost of ownership : Low air leakage, optimal airflow characteristics, and less pressure drop allow smaller more efficient moving equipment Inherently stronger, allowing the use lighter gauge, costly metals Efficiently manufactured from strip steel to any diameter Spiral duct's smooth interior traps dust is easier clean Broad Range Applications : Commercial Industrial Chemical Underground Bulk materials handling Pipe The versatility duct has lead its in a wide range applications: Commercial–the primary commercial applications for HVAC. can now be found numerous including: Restaurants Churches Sports facilities Community centers Clinics hospitals Schools universities Retail stores malls entertainment Office buildings warehouses And many Industrial–Spiral pipe's ability handle high positive negative pressures led industrial HVAC Removal chemical fumes other environmental toxins airborne particulates Removal manufacturing byproducts such as sawdust wood shaving

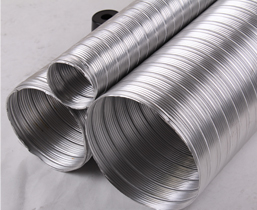

The semi-rigid aluminum duct is ideal when all required by code in some gas and electric dryer applications. This totally non combustible with a maximum operating temperature of 435°F. product constructed special fabrication produces continous lock seam that permits the to be pulled open, compressed re-bent. Advantages Non-combustible Easy installation Can bent freely for shipping convinience Applicable most ducting system

Moradon Flexible Aluminum ducting is made of a heavy duty aluminum foil laminate bonded with hight quality adhesive and reinforced hugh carbon corrosion proof spring wire. Designed only 1” (approximaterly 25 mm) between the wires. The duct fully flexible, compressible extendable air duct. In addition to its flexible nature, need for elbows eliminated, allowing ease installation difficult reach area. It cuts easily knife snips comes in two series. Single (FS-Series) which are up one layer PET whereas Double (FD-Series) ply multi-layered alluminum makes it more durable. This system popular because easy install economical Advantages : Easy Can be bent into any configuration ship